By now, each of us has encountered it: bags, backpacks, clothing with the mention of the mysterious material "rPET" in the product description. And more and more brands are using this material for their textile products.

Perhaps you've heard that it's related to environmental protection, or material recycling. But what exactly does the abbreviation rPET mean? How can a used plastic bottle be transformed into practical fabric? What are the properties of this fabric? And why does even National Geographic use rPET in their backpacks and bags?

Let's try to figure it out.

So, what is rPET?

rPET is an abbreviation for recycled polyethylene terephthalate.

Not that it makes it any clearer. Let's put it in simpler terms:

Polyethylene terephthalate is one of the most popular types of plastic in the world, and you're probably already familiar with it. It's used in many areas, but mostly for making plastic bottles and containers. Chances are, if you look at the bottom of a regular water bottle you have at hand, you'll find this marking:

This is exactly that type of plastic. It means that it can be 100% recycled. And rPET is the result of such a process.

Okay, but how exactly does this recycling process happen?

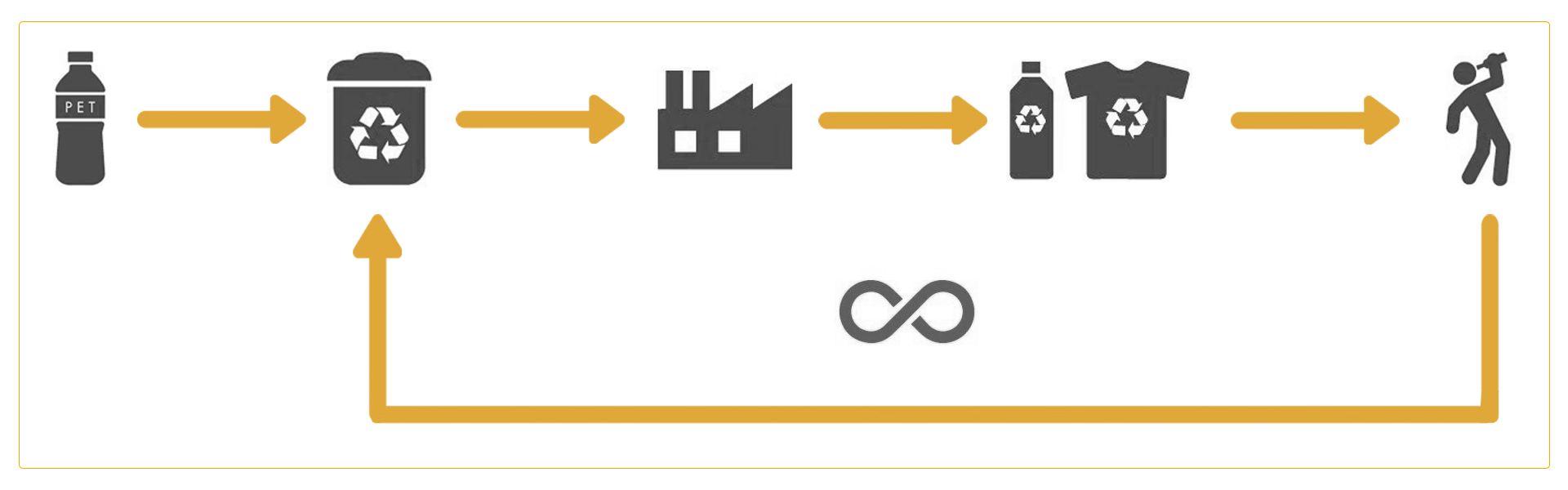

Suppose a consumer has used our plastic bottle and is also a responsible citizen of our planet, so they sort their trash. Under such a condition, the journey of our bottle will be long and perhaps even endless, as rPET is also fully recyclable. A good alternative to scenarios where the bottle ends up in the world's ocean waters or, for instance, on one of the already huge garbage dumps, right?

Step-by-step, the recycling process goes as follows:

- Collecting PET waste

- Then, the plastic is sorted, cleaned, and broken down into small granules.

- Next, these granules are melted into thin threads.

- And then from these threads they get... polyester, which you are probably already familiar with.

So, does the rPET label in textile products actually mean polyester?

Exactly. But with the note "recycled." This doesn't affect the properties or quality of the material, but there are significant differences from an environmental standpoint:

- No new Earth resources are used to produce such material.

- Manufacturing fabric from recycled plastic is more energy-efficient by 75%, CO2 by 40%, and water by 90% compared to producing polyester from raw materials.

- Reducing the amount of waste in landfills.

Furthermore, polyester as a material is particularly relevant for making bags and backpacks, thanks to its properties and advantages.

- This material is strong and durable;

- Holds its shape well and doesn't crease;

- Lightweight;

- Resistant to pilling;

- Water-resistant

- Dries quickly.

Mixing with other materials allows for fabrics with virtually any characteristics. For example, when mixed with cotton, the texture of the fabric changes, and it becomes even stronger.

National Geographic, as a flagbearer of environmental protection principles, reduced consumption, and eco-friendly manufacturing, also uses rPET in its products, which you can find and purchase at the Bagston store.